Course

CSWIP 3.1 (Welding Inspector)

AWS - CSWIP BRIDGING

Focusing on welding inspection, defect identification, and quality control of welded structures.

ENQUIRE NOW

CSWIP 3.2.2 / CSWIP 3.2.1 (Senior Welding Inspector)

Focusing on in-depth welding inspection techniques, welding procedures, and quality assurance systems.

ENQUIRE NOW

BGAS GRADE 1 & GRADE 2 (Painting Inspector)

Focusing on the inspection of protective coatings and painting systems used in industrial environments.

ENQUIRE NOW

Lead Auditing

The process of planning, conducting, and managing audits of management systems to ensure compliance with standards like ISO. Lead auditors are responsible for guiding the audit team, ensuring roles are clearly defined, and that the audit objectives are met efficiently. They prepare comprehensive audit reports, highlight non-conformities.

View MoreENQUIRE NOW

WPS / WPQR / WPQ

WPS (Welding Procedure Specification) is a documented guideline detailing how welding should be performed. WPQR (Welding Procedure Qualification Record) and WPQ (Welder Performance Qualification) are records validating the WPS and confirming the welder's ability to produce sound welds according to the specified procedure.

View MoreENQUIRE NOW

Visual Testing (VT)

Inspecting surfaces for visible defects like cracks, corrosion, misalignments, etc. Adequate lighting and clear access to the surface are essential to ensure accurate inspection; poor visibility may lead to missed defects.

ENQUIRE NOW

Eddy Current Testing (ET)

Eddy current testing that uses electromagnetic induction to detect surface and near-surface flaws in conductive materials. Variations in eddy current flow reveal defects or changes in material properties.

ENQUIRE NOW

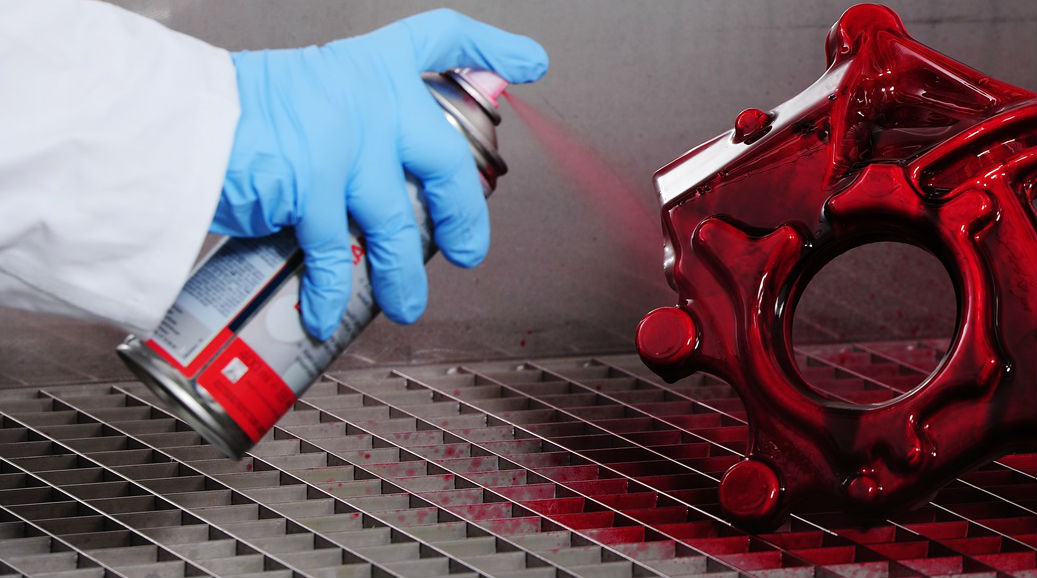

Penetrant Testing (PT)

Reveals surface-breaking defects using a dye or fluorescent penetrant. The dye seeps into cracks and becomes visible under inspection, highlighting flaws on the material's surface.

ENQUIRE NOW

Magnetic Particle Testing (MT)

Magnetic particle testing used to detect surface and near-surface defects in ferromagnetic materials. It involves magnetizing the material and applying ferrous particles that gather at discontinuities.

ENQUIRE NOW

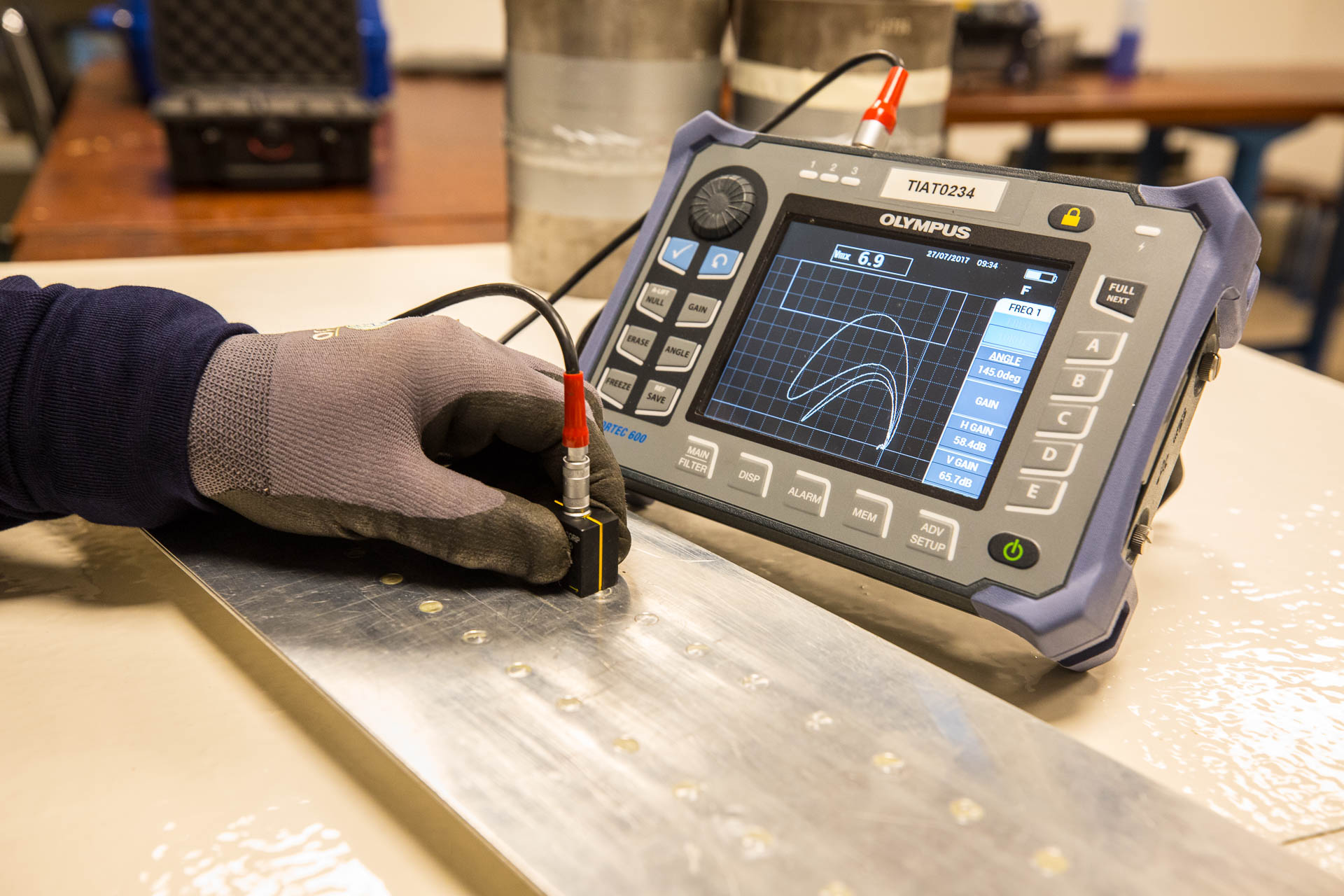

Ultrasonic Testing (UT)

Ultrasonic testing that uses high-frequency sound waves to detect internal flaws or discontinuities in materials. Reflected sound waves from defects are analyzed to determine their location and size.

ENQUIRE NOW

Radiographic Testing (RT)

Radiographic testing that uses X-rays or gamma rays to produce images of a material's internal structure. It helps identify internal flaws such as cracks, voids, or inclusions.

ENQUIRE NOW

Radiographic Testing Film Interpretation (RTFI)

Process of analyzing radiographic images (X-ray or gamma ray films) to detect and evaluate internal discontinuities or defects in a material or weld.

ENQUIRE NOW